- Home Page

- Company Profile

-

Our Products

- Microscope

- CONFOCAL MICROSCOPES

- Trinocular Upright Metallurgical Microscope

- Portable Grooved Metallurgical Microscope

- Cell Culture Imaging System

- Metallurgical Microscope

- Projection Microscope

- Student Stereo Microscope

- BINOCULAR STEREO ZOOM MICROSCOPE

- PCB Inspection Video Stereoscope Microscope

- SPINNERET MICROSCOPE

- Penta Head Microscope/ Multi view Head Microscope

- Research Polarising Microscope

- Senior Dissecting Microscope

- Dissecting Microscope

- Motorized Comparision Microscope

- Sieves Digital Microscopes

- Advance Inverted Tissue Culture Microscope

- Advance Stereo Zoom Microscope

- Student Projection Microscope

- Inverted Metallurgical Microscope

- Measuring Microscope

- Digital Spinneret Inspection Microscope

- Portable Inverted Tissue Culture Microscope

- Binocular Inverted Tissue Culture Microscope

- Student Compound Microscope

- Trinocular Stereozoom Microscope

- Advanced Research Microscope

- Gemological Microscope

- Polarizing Projection Microscope

- Senior Inspection Spinneretscope

- Confocal Microscope

- Senior Projection Microscope

- Toolmaker's Microscope

- Research Microscope

- Stereo Inspection Microscope

- Student Medical Microscope

- Digital Biological Microscope RXLr-4D

- Toolmaker Microscope Large

- Stereo Inspection Scope

- Trinocular Research Microscope

- Portable Metallurgical Microscope

- Binocular Research Microscope

- Student School Microscope

- Inverted Tissue Culture Microscope

- Projection Microscope

- Laboratory Microscope

- Decca Head Microscope

- Advanced Research Material Microscope

- Microtomes

- Semi Automatic Rotary Microtome

- Senior Precision Rotary Microtome

- Rocking Microtome

- Rotary Microtome Erma Type

- Freezing Microtome

- Fully Automatic Rotary Microtome

- Manual Rotary Microtome RMT-25

- Advance Rotary Microtome

- Hand Table Microtome

- Knife Sharpener Microtome

- Sliding Miocrotome

- Slide Staining Machine

- Rotary Microtome

- CRYOSTAT MICROTOME

- Optical Instruments

- Tissue Processor Machine

- Microscope Accessories

- Histopathological Equipment

- Lab Instrument

- Radical Digital Turbidity Meter

- Radical Microprocessor Dissolved Oxygen Meter

- Digital Photo Colorimeter

- Tap Density Tester

- Serological Water Bath

- Magnetic Stirrer

- Dual Channel Flame Photometer

- pH or mv or Conductivity

- Round Centrifuge

- Radical Disintegration Test Apparatus

- Digital Slide Scanner

- Precision Water Bath

- Incubator Shaker Water Bath

- Hemoglobin meter

- Microprocessor Colony Counter

- PASS BOX DYNAMIC

- Radical Microprocessor Colony Counter

- Bulk Density Apparatus

- Laboratory Rectangular Hot Plates

- Tablet Dissolution Test Apparatus

- Hemoglobin Meter (Sahli's)

- Micro Centrifuge 16000 R.P.M.

- Revolutionary General Purpose Digital Centrifuge

- Vortex Shaker

- Rectangular Water Bath

- Heating Mantel

- Digital Spectrophotometer

- Haematocrit Centrifuge

- Water Distillation with Metal Heater

- Hand Specimen Leveler Press

- GROSSING TABLE

- COOLING PLATE

- MICROPROCESSOR PH METER

- DIGITAL FLAME PHOTOMETER

- pH/mV/TEMPERATURE TESTER

- DIGITAL PH, CONDUCTIVITY & TEMPERATURE METER

- Radical Auto Karl Fischer Titrimeter

- Stereo Zoom Microscope

- Jewellery Making Microscope

- Binocular Stereo Microscope

- Advanced Stereo Zoom Microscope

- Articulated Trinocular Stereo Zoom Microscope

- Digital 3D Inspection Microscope

- Binocular Stereo Microscopes

- Motorized Stereo Microscopes

- Trinocular Microscope

- Stereo Inspection Microscope

- Stereo Microscope

- Digital 3D Inspection Microscope RSZ-3D

- Stereo Zoom Microscope RSM-8

- Polarising Microscopes

- Lab Consumables

- Profile Projector

- Optical Profile Projector

- Vertical Profile Projector

- Profile Projector RPP-500

- Profile Projector

- PROFILE PROJECTOR

- Universal Profile Projector

- Bench Type Profile Projector

- Charpy Profile Projector

- High Sharpness Profile Projector

- Profile Projector

- Horizontal Profile Projector

- Digital Profile Projector

- Radical Profile Projector

- Coaxial Profile Projector

- Anotomy Model

- Metallurgical Microscope

- Microscope

- Contact Us

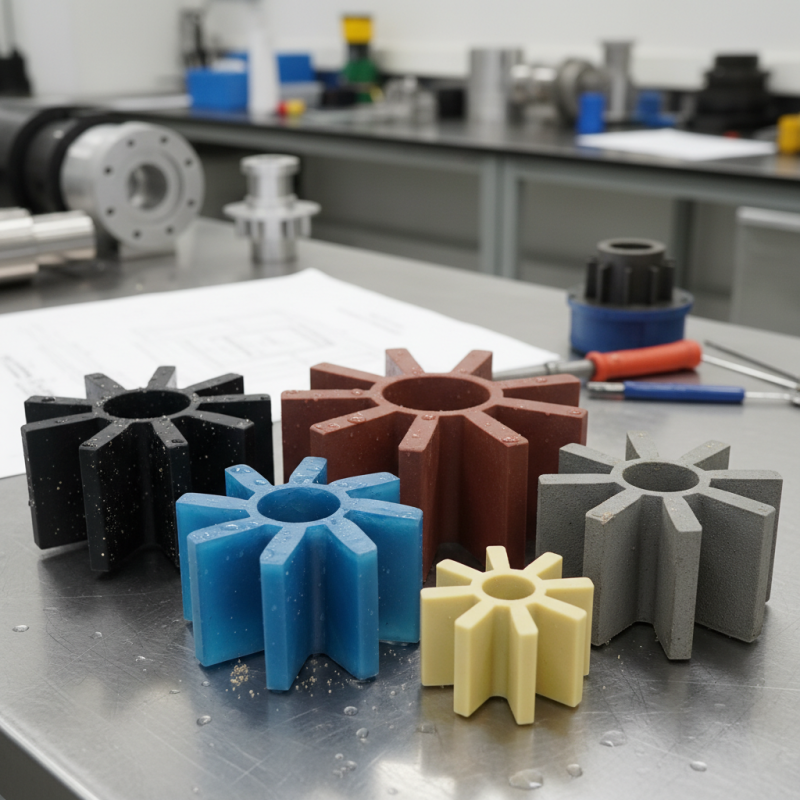

How to Choose the Best Rubber Pump Impeller for Your Needs?

Choosing the right Rubber Pump Impeller can significantly impact performance. John Smith, a leading expert in pump engineering, suggests, “The right impeller transforms your pump’s efficiency.” This highlights the importance of selecting an appropriate Rubber Pump Impeller, tailored to specific needs.

Understanding your application is crucial. Different tasks may require unique design features. Performance can suffer if the wrong impeller is chosen. For instance, using an impeller tailored for low flow in a high flow situation can lead to inefficiencies.

Quality also plays an essential role. Not all Rubber Pump Impellers are created equal. Some may wear quickly under certain conditions. It's essential to consider factors like material composition and design specifics. Evaluating brands and their reputations can provide valuable insights.

Table of Contents [Hide]

Understanding the Role of Rubber Pump Impellers in Fluid Dynamics

Rubber pump impellers are crucial in fluid dynamics. They help to move liquids through systems efficiently. The choice of material affects durability and performance. Industry reports indicate that over 50% of pump failures are due to inadequate components. This highlights the need for careful selection.

When considering rubber impellers, flexibility and resistance are vital. Some rubbers handle abrasion better than others. Research shows that compounds with high tensile strength can extend the lifespan of an impeller by 30%. However, not all environments are suitable for all types of rubber. Temperature variations and chemical exposure can impact their effectiveness.

Many users overlook the importance of maintenance. Regular inspections can identify wear and tear early. Ignoring these signs can lead to system inefficiencies. A recent study noted that 40% of pumps suffer from cavitation caused by damaged impellers. This significantly affects performance and can lead to costly repairs. Choosing the right rubber impeller means considering your specific requirements and environmental factors.

Key Factors to Consider When Selecting a Rubber Pump Impeller

Choosing the right rubber pump impeller is critical for efficiency and performance. Several factors can influence this decision. Understanding material durability is essential. For instance, the Shore hardness of rubber can affect wear resistance. A report by the Hydraulic Institute shows that impellers with higher hardness ratings can last longer in abrasive environments.

Another important consideration is the pump’s specific application. Different applications require varying levels of flow rates and pressure. Assess your system requirements carefully. A mismatch can lead to inefficiencies, causing operational failures.

Tip: Always check compatibility with your existing system. Ensure that the impeller can handle the required fluid viscosity and temperature.

Size is also a key factor. Impeller diameter directly affects flow rate and efficiency. A larger impeller often results in higher capacity but can be less efficient at lower flow rates. Balancing size with operational needs is crucial for optimal performance.

Tip: Don’t overlook the suction capabilities of the impeller. Insufficient suction can lead to cavitation, damaging your pump.

In summary, selecting the best rubber pump impeller involves multiple factors. It’s not just about fitting components together; it’s about understanding the unique demands of your specific application. Be informed and make choices that prioritize efficiency and longevity.

Different Types of Rubber Pump Impellers and Their Applications

When selecting a rubber pump impeller, understanding the various types and their applications is crucial. Common types include open impellers, closed impellers, and semi-open impellers. Open impellers are efficient for handling fluids with solid particles. They are common in wastewater treatment. Closed impellers offer higher efficiency and better pressure capabilities, making them suitable for clean fluids. Semi-open impellers strike a balance, providing versatility for diverse applications.

According to industry reports, rubber impellers are widely used in agricultural irrigation and chemical processing. Their engineered designs allow for durability against harsh chemicals. In fact, studies show that 70% of businesses experience downtime due to improper impeller selection. An ideal impeller should reduce maintenance cost and increase operational efficiency.

However, challenges exist. Miscalculations in fluid dynamics can lead to cavitation, damaging the impeller. Moreover, not all rubber materials can withstand extreme temperatures. It's essential to evaluate the specific environmental conditions of your application. Choosing the right impeller often involves trial and error. A thorough analysis of your needs is vital for optimal performance.

Evaluating Performance: Size, Shape, and Material of Impellers

Choosing the right rubber pump impeller is crucial for optimal performance. When evaluating impellers, size, shape, and material play significant roles. The size directly influences flow rates. Larger impellers can move more fluid, but they require more power. If your pump struggles, a smaller impeller might be a better fit.

Shape is another vital factor. Impellers come in various designs. Some are more efficient for certain tasks than others. For instance, a well-designed open impeller can handle solids better. However, it may decrease efficiency in clean fluids. You must consider the specific application to make the best choice.

Material also counts. Rubber can provide flexibility and durability. Yet, not all rubber types are the same. Some can withstand harsh chemicals, while others cannot. Understanding your operating environment is key. Are you working with substances that might degrade the material? This consideration may lead you to rethink your selection. Proper evaluation and reflection on these aspects will ensure you choose the best rubber pump impeller for your needs.

Maintenance Tips for Ensuring Longevity of Rubber Pump Impellers

Maintaining rubber pump impellers is crucial for their longevity. Regular inspections can reveal wear or damage. Pay attention to any signs of cracking or brittleness in the rubber. These issues can worsen over time without intervention. It's essential to address problems early to avoid costly repairs later.

Cleaning the impeller should be a routine task. Dirt and debris can accumulate, affecting performance. Removing these contaminants can enhance efficiency. Use a soft brush to gently clean the surfaces. Harsh chemicals can degrade rubber, so stick to mild soap and water.

Lubrication is another key aspect. Proper lubrication can reduce friction and wear. However, over-lubricating can lead to build-up. Strike a balance and apply just enough. Regularly check for any unusual noises during operation; they may indicate underlying issues. Keeping a maintenance log could help track changes and improvements over time.

Article Source:

Contact Us

- 9th Milestome, Ambala-Jagadhri Road, P.O.- Khudda Kalan, NH-444A,Ambala Cantt - 133104, Haryana, India

- Phone : 08045479132

- Mrs POONAM BHANDARI (Incharge - Mktg & Sales )

- Mobile : 08045479132

- Send Inquiry

GST : 06AACCR8985N1ZI

Our Products

RADICAL SCIENTIFIC EQUIPMENTS PVT. LTD.

All Rights Reserved.(Terms of Use)

Developed and Managed by Infocom Network Private Limited.

Developed and Managed by Infocom Network Private Limited.