- Home Page

- Company Profile

-

Our Products

- Microscope

- CONFOCAL MICROSCOPES

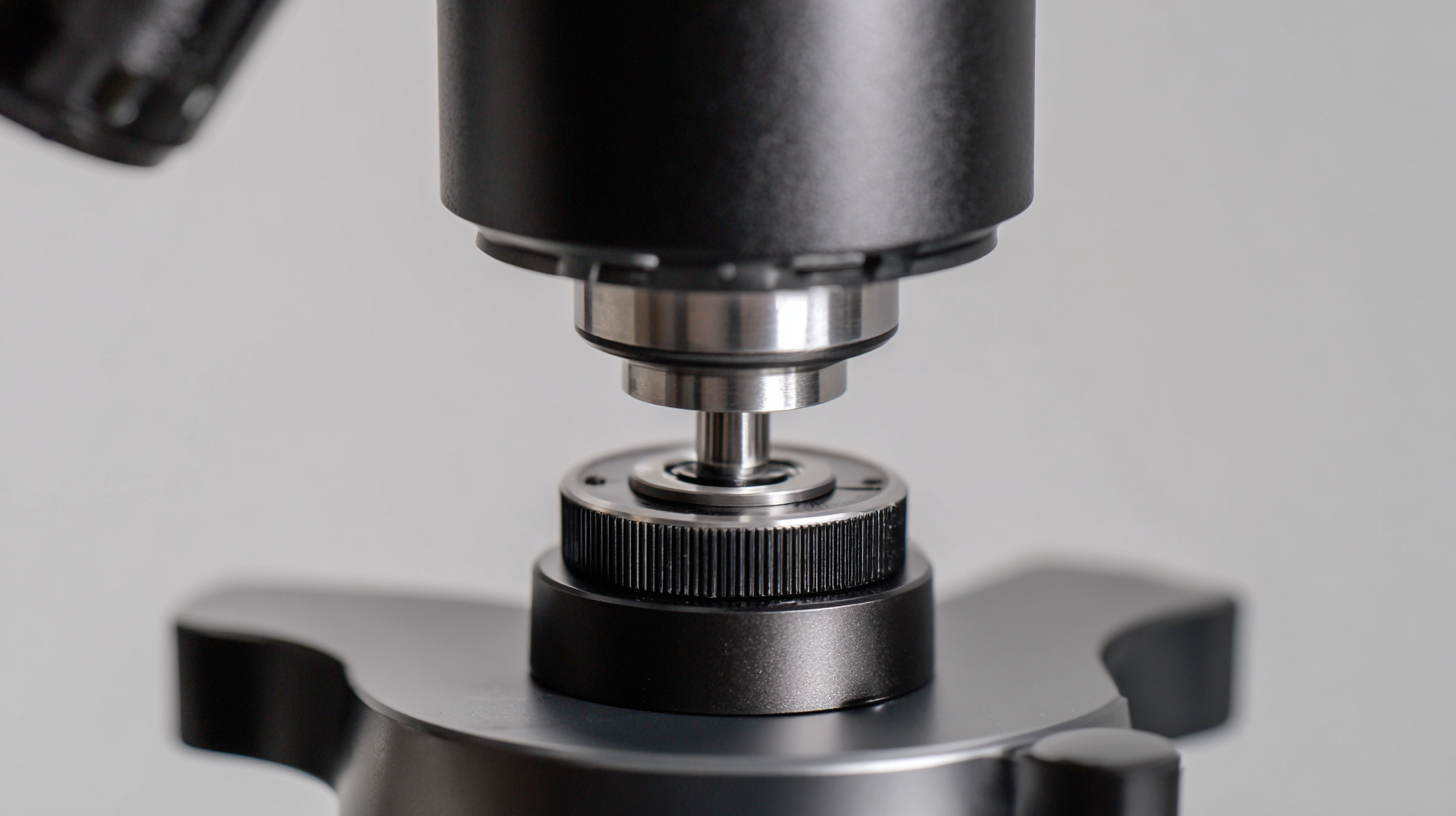

- Trinocular Upright Metallurgical Microscope

- Portable Grooved Metallurgical Microscope

- Cell Culture Imaging System

- Metallurgical Microscope

- Projection Microscope

- Student Stereo Microscope

- BINOCULAR STEREO ZOOM MICROSCOPE

- PCB Inspection Video Stereoscope Microscope

- SPINNERET MICROSCOPE

- Penta Head Microscope/ Multi view Head Microscope

- Research Polarising Microscope

- Senior Dissecting Microscope

- Dissecting Microscope

- Motorized Comparision Microscope

- Sieves Digital Microscopes

- Advance Inverted Tissue Culture Microscope

- Advance Stereo Zoom Microscope

- Student Projection Microscope

- Inverted Metallurgical Microscope

- Measuring Microscope

- Digital Spinneret Inspection Microscope

- Portable Inverted Tissue Culture Microscope

- Binocular Inverted Tissue Culture Microscope

- Student Compound Microscope

- Trinocular Stereozoom Microscope

- Advanced Research Microscope

- Gemological Microscope

- Polarizing Projection Microscope

- Senior Inspection Spinneretscope

- Confocal Microscope

- Senior Projection Microscope

- Toolmaker's Microscope

- Research Microscope

- Stereo Inspection Microscope

- Student Medical Microscope

- Digital Biological Microscope RXLr-4D

- Toolmaker Microscope Large

- Stereo Inspection Scope

- Trinocular Research Microscope

- Portable Metallurgical Microscope

- Binocular Research Microscope

- Student School Microscope

- Inverted Tissue Culture Microscope

- Projection Microscope

- Laboratory Microscope

- Decca Head Microscope

- Advanced Research Material Microscope

- Microtomes

- Semi Automatic Rotary Microtome

- Senior Precision Rotary Microtome

- Rocking Microtome

- Rotary Microtome Erma Type

- Freezing Microtome

- Fully Automatic Rotary Microtome

- Manual Rotary Microtome RMT-25

- Advance Rotary Microtome

- Hand Table Microtome

- Knife Sharpener Microtome

- Sliding Miocrotome

- Slide Staining Machine

- Rotary Microtome

- CRYOSTAT MICROTOME

- Optical Instruments

- Tissue Processor Machine

- Microscope Accessories

- Histopathological Equipment

- Lab Instrument

- Radical Digital Turbidity Meter

- Radical Microprocessor Dissolved Oxygen Meter

- Digital Photo Colorimeter

- Tap Density Tester

- Serological Water Bath

- Magnetic Stirrer

- Dual Channel Flame Photometer

- pH or mv or Conductivity

- Round Centrifuge

- Radical Disintegration Test Apparatus

- Digital Slide Scanner

- Precision Water Bath

- Incubator Shaker Water Bath

- Hemoglobin meter

- Microprocessor Colony Counter

- PASS BOX DYNAMIC

- Radical Microprocessor Colony Counter

- Bulk Density Apparatus

- Laboratory Rectangular Hot Plates

- Tablet Dissolution Test Apparatus

- Hemoglobin Meter (Sahli's)

- Micro Centrifuge 16000 R.P.M.

- Revolutionary General Purpose Digital Centrifuge

- Vortex Shaker

- Rectangular Water Bath

- Heating Mantel

- Digital Spectrophotometer

- Haematocrit Centrifuge

- Water Distillation with Metal Heater

- Hand Specimen Leveler Press

- GROSSING TABLE

- COOLING PLATE

- MICROPROCESSOR PH METER

- DIGITAL FLAME PHOTOMETER

- pH/mV/TEMPERATURE TESTER

- DIGITAL PH, CONDUCTIVITY & TEMPERATURE METER

- Radical Auto Karl Fischer Titrimeter

- Stereo Zoom Microscope

- Jewellery Making Microscope

- Binocular Stereo Microscope

- Advanced Stereo Zoom Microscope

- Articulated Trinocular Stereo Zoom Microscope

- Digital 3D Inspection Microscope

- Binocular Stereo Microscopes

- Motorized Stereo Microscopes

- Trinocular Microscope

- Stereo Inspection Microscope

- Stereo Microscope

- Digital 3D Inspection Microscope RSZ-3D

- Stereo Zoom Microscope RSM-8

- Polarising Microscopes

- Lab Consumables

- Profile Projector

- Optical Profile Projector

- Vertical Profile Projector

- Profile Projector RPP-500

- Profile Projector

- PROFILE PROJECTOR

- Universal Profile Projector

- Bench Type Profile Projector

- Charpy Profile Projector

- High Sharpness Profile Projector

- Profile Projector

- Horizontal Profile Projector

- Digital Profile Projector

- Radical Profile Projector

- Coaxial Profile Projector

- Anotomy Model

- Metallurgical Microscope

- Microscope

- Contact Us

The Future of Precision with Best Digital Inspection Microscopes

In an era where precision is paramount in various industries, the emergence of Digital Inspection Microscopes has transformed the landscape of quality assurance and product development. As a symbol of excellence in Chinese manufacturing, these advanced instruments not only embody technical prowess but also showcase the strength of China's export capabilities in the global market.

The continuous evolution of digital microscopy technology allows for enhanced imaging and measurement accuracies, which are crucial for industries such as electronics, automotive, and medical devices. As we delve into the future of precision with digital inspection solutions, we will explore the latest innovations, applications, and how these remarkable tools are setting new standards for inspection processes worldwide.

Embracing the journey of Digital Inspection Microscopes signifies not only a commitment to superior quality but also a strategic advantage for businesses looking to maintain a competitive edge in an increasingly demanding market.

Table of Contents

[Hide]

Emerging Technologies Shaping Digital Inspection Microscopes by 2025

The future of digital inspection microscopes is being significantly influenced by emerging technologies that promise enhanced precision and usability by 2025. According to a report by MarketsandMarkets, the digital microscope market is expected to grow from USD 1.1 billion in 2020 to USD 1.6 billion by 2025, at a compound annual growth rate (CAGR) of 7.6%. This growth is driven by advancements in imaging technologies, increasing demand for quality control in manufacturing, and the integration of artificial intelligence (AI) for automated inspections.

Innovations such as 3D imaging and machine learning algorithms are transforming how digital inspection microscopes function. Companies like Zeiss and Nikon are pioneering the development of microscopes that offer real-time analysis and measurement capabilities, vastly improving accuracy. Furthermore, the use of optical coherence tomography (OCT) technology is expected to enhance image resolution and penetration depth in biological samples, which is invaluable for the medical field. As these technologies continue to evolve, the landscape of precision measurement and defect inspection will shift dramatically, providing industries with tools that not only meet but exceed current quality assurance standards.

Key Features to Look For in Next-Gen Digital Microscopes

The field of digital microscopy is rapidly evolving, with next-generation models boasting enhanced capabilities that redefine precision in inspection. When considering the best digital inspection microscopes, several key features stand out. First, the resolution is paramount; advanced models now offer 4K ultra-high-definition imagery that captures even the smallest details with remarkable clarity, making it easier for users to inspect and measure intricate specimens. The recent introduction of a new digital microscope capturing live images at impressive frame rates is a testament to the push for efficiency and precision in microscopy.

Another critical feature is the light source. Modern digital microscopes are adopting high color-rendering LED light sources, which provide optimal illumination for observing fine details and textures. This not only enhances the visualization quality but also ensures consistent, reliable results across various sample types. Additionally, increased field of view and improved throughput capabilities are becoming standard in next-gen models, enabling users to scan larger areas without sacrificing detail.

Tips: When choosing a digital inspection microscope, prioritize models that offer high resolution and advanced imaging software for accurate measurements. Also, consider the type of light source, as LED options can significantly enhance sample visibility. Lastly, be sure to evaluate the microscope's user interface and software capabilities to streamline your workflow and maximize efficiency.

The Impact of AI and Machine Learning on Precision Inspection

In recent years, the integration of AI and machine learning into digital inspection microscopes has revolutionized precision inspection, making it faster and more accurate than ever before. Advanced algorithms can analyze images and data in real-time, identifying defects and anomalies with an unprecedented level of detail. This transformative technology is not only enhancing the quality control processes across various industries but also reducing human error, ensuring that inspection outcomes are more reliable.

Tip: To maximize the benefits of AI-driven inspection systems, it’s essential to invest in training for your team. Understanding how to interpret data outputs and leverage advanced features will improve the inspection process and increase productivity.

Moreover, as digital inspection microscopes become more sophisticated, the potential for predictive analytics grows. By utilizing machine learning, these systems can learn from past inspection data to make informed predictions about potential issues before they arise. This proactive approach not only saves time but also helps in minimizing waste and downtime.

Tip: Regularly updating the software and algorithms used in these microscopes is crucial. Staying current ensures that your inspection processes benefit from the latest technological advancements and maintain high standards of precision.

The Future of Precision: Impact of AI and Machine Learning on Precision Inspection

Top Applications of Digital Inspection Microscopes in Various Industries

Digital inspection microscopes are revolutionizing quality control across various industries, providing precision and clarity that traditional optical microscopes cannot match. In the manufacturing sector, these advanced tools facilitate real-time inspection of components, ensuring that parts meet stringent specifications. By capturing high-resolution images, engineers can quickly detect defects or deviations in materials, leading to improved productivity and reduced wastage.

Digital inspection microscopes are revolutionizing quality control across various industries, providing precision and clarity that traditional optical microscopes cannot match. In the manufacturing sector, these advanced tools facilitate real-time inspection of components, ensuring that parts meet stringent specifications. By capturing high-resolution images, engineers can quickly detect defects or deviations in materials, leading to improved productivity and reduced wastage.

In the field of electronics, digital inspection microscopes play a crucial role in the assembly and quality assurance of circuit boards. Their ability to magnify fine details allows technicians to inspect solder joints and component placements with unparalleled accuracy. This level of scrutiny helps maintain high performance standards in electronic devices, which are increasingly complex and compact.

Moreover, the medical industry benefits significantly from these microscopes, particularly in histology and pathology. Digital inspection allows for detailed examination of tissue samples, enhancing diagnostic accuracy and supporting advanced research initiatives. By integrating imaging software, pathologists can analyze samples with better efficiency, leading to faster and more reliable diagnoses. Overall, the applications of digital inspection microscopes are diverse, making them indispensable tools in various fields.

Best Practices for Choosing and Using Digital Inspection Microscopes

When it comes to choosing and using digital inspection microscopes, understanding your specific needs is crucial. Start by assessing the type of materials and samples you will be inspecting. Different microscopes come with various magnification capabilities and resolution options. For instance, if you are working in a semiconductor environment, look for models that provide high resolution and detail at a nanoscale level.

Tip: Always check the specifications of the microscope and ensure that it matches your application requirements. It's also advisable to consider ergonomics, as a comfortable workstation can enhance productivity during long inspection periods.

Once you've selected the right microscope, it's essential to familiarize yourself with best practices for usage. Regular calibration and maintenance of the equipment will ensure longevity and accuracy in measurements. Additionally, make the most of digital features such as image capturing and software analysis to enhance your workflow.

Tip: Take advantage of tutorials and training provided by the manufacturer to master the software tools that accompany your digital microscope. This will not only improve your skills but also provide more accurate insights into your inspections.

Contact Us

- 9th Milestome, Ambala-Jagadhri Road, P.O.- Khudda Kalan, NH-444A,Ambala Cantt - 133104, Haryana, India

- Phone : 08045479132

- Mrs POONAM BHANDARI (Incharge - Mktg & Sales )

- Mobile : 08045479132

- Send Inquiry

GST : 06AACCR8985N1ZI

Our Products

RADICAL SCIENTIFIC EQUIPMENTS PVT. LTD.

All Rights Reserved.(Terms of Use)

Developed and Managed by Infocom Network Private Limited.

Developed and Managed by Infocom Network Private Limited.